The importance of extractables & leachables testing has grown with amplified utilization of single-use methods. Therefore, E&L screening is usually a regulatory requirement to display that leachable impurities from plastic components Utilized in the processing of a clinical product or service don’t interfere Using the Lively pharmaceutical ingredient, ensuring individual security.

Such as: Solution A has actually been cleaned out. The product A has a typical every day dose of 10mg along with the batch measurement is two hundred kg.

Purified drinking water shall be used being a ultimate rinse for tools, for use from the manufacture of non-sterile items.

L = Surface area area of kit prevalent for the two the items (past & upcoming product) in equipment chain

Rinse sampling is a method of sampling that’s done indirectly. It entails the collection and subsequent Evaluation of the rinse h2o or solvent Utilized in the put up-cleaning clean of the products.

Just about every is a high quality-controlled and accepted document that may be accustomed to qualify style and installation qualification and to determine the necessity for leachables testing.

Comparison of Extractables Protocols It is Sartorius’ aim to supply you with essentially the most in depth extractables knowledge probable to simplify their procedure qualification and validation.

Setting up a sturdy Cleaning Software: The muse of effective cleaning validation is a strong cleaning software that features perfectly-documented cleaning treatments, acceptable cleaning agents, and validated cleaning methods.

The timeframe for storage of uncleaned machines for cleaning shall be recognized (unclean equipment might be saved as many as website seventy two hrs).

Machines Compatibility: The selected method should not problems the products. Components like content check here of construction and design constraints are thought of.

I'm able to revoke my consent Anytime with effect for the long run by sending an e-mail to unsubscribe@sartorius.com or by clicking to the "unsubscribe" link in e-mails I've received.

The resultant benefit could be the residue of previous product/s in milligram from complete tools/aspect of equipment cleaned.

eight.3 The time period and circumstances for storage of unclean equipment just before cleaning, and time amongst cleaning and devices reuse, need to sort part of the validation of cleaning strategies.

It really is tough to present assurance the contaminants is going to be dislodged within the products area uniformly. In addition, In the event the particles of the contaminant or residue are big ample, they may not be uniformly dispersed while in the placebo batch.

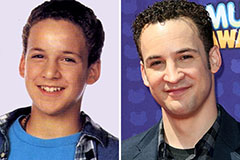

Ben Savage Then & Now!

Ben Savage Then & Now! Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now!